RFID Technology In Retail Small or Big Industry

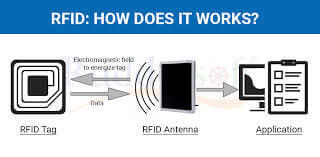

Radio-frequency identification (RFID)is the wireless non-contact use of radiofrequency waves to transfer data that uses electromagnetic fields to automatically identify and track tags attached to objects. The tags contain electronically stored information. Passive tags collect energy from a nearby RFID system reader’s interrogating radio waves.

Tagging items with RFID tags allows users to automatically and uniquely identify and track inventory and assets. RFID takes auto-ID technology to the next level by allowing tags to be read without a line of sight and, depending on the type of RFID, having a read range between a few centimeters to over 20+ meters.

ad

RFID Short History

RFID has come a long way from its first application of identifying airplanes as friends or foes in World War II. The basis of RFID technology was the combination of radio broadcast technology and radar. Basically, the process is: a transmitter sends a signal which is reflected back by a transponder in the passive RFID system. Or this transponder answers broadcasting a signal in an active RFID system.

Not only does the technology continue to improve year over year, but the cost of implementing and using an RFID system continues to decrease, making RFID more cost-effective and efficient.

ad

Mario W. Cardullo claims to have received the first U.S. patent for an active RFID tag with rewritable memory on January 23, 1973.

📚 Also Read: What is RFID blocking, and do you need it?

RFID in Retail![RFID In Retail]()

RFID tags carry unique product numbers. If consumers pay for goods with a credit, debit or shopper’s discount card, retailers can link the purchases to the recorded RFID data and use that marketing information to map out individual consumers’ movements through a store.

Retailers are always on the lookout for ways to test and implement technology to operate more efficiently, set themselves apart from the competition and improve the shopping experience.

Today we will see how RFID system is transforming the retail industry on its new heights.

1. Store inventory management and data analysis

- Improvement in overall accuracy — With the help of RFID in retail, it can transform the in-store inventory accuracy to upwards of 98%, approaching that of warehouses. The typical retail inventory process is very manual, time-consuming, and only done at predetermined intervals. Historical data shows that for every ~3% improvement in in-store inventory accuracy, you can expect a ~1% increase in sales. Typical retailers operate at ~70% accuracy by year-end (2–3% reduction in accuracy per month), leaving significant opportunity for a positive impact on sales.

- Receiving — Because RFID antennas and wands do not require line of sight to scan RFID tags, shipments to the store can be instantly and accurately received into inventory. This is a huge win compared to a time-sucking individual carton and item scanning, or even worse, blind receipts.

- Finding items — Handheld RFID wands typically have the ability to track items in the store using a system akin to metal detectors, beeping faster as the wand approaches a given item. More complex systems of fixed antennas throughout a store can also be set up to pinpoint a specific tag’s location.

- Cycle count time — Since the line of sight is not necessary and RFID antennas can work at a distance, a cycle count can be done significantly faster and more accurately than any traditional processes.

- Removal of formal inventory counts — RFID readers are accurate enough such that RFID-based inventory counts may be allowed by your auditor after showing a history of accuracy.

- Auto reorders at safety stock levels — Because your overall accuracy is improved, the rules that are set up for replenishment orders can be set and forgotten in-lieu of manual spot-checking or ensuring replenishments are needed.

2. Store operations

- Spread breadth of available products while reducing depth — thinking about a product like men’s jeans, one style may have 10 different widths, 10 different lengths, and 10 different colors. It will be impossible to keep any significant amount of inventory for all variations displayed. Inevitably many will stock out on the floor and others will have no movement. This may change on a day-to-day basis with some trends, but not enough to make impactful floor inventory decisions. With RFID system in place, employees can be notified when a specific combination is no longer available on the floor (or has low inventory), where to find it in the backroom, and exactly how many to pull, on a nearly instantaneous and continuous basis.

- BOPIS and ship from store — Both buy-online-pick-up-in-store and ship from the store are customer expectations approaching a must-have capability for retailers. If the business cannot trust their inventory accuracy, they cannot consistently deliver these capabilities. In simplest terms, without accurate, real-time inventory counts, a retailer could be selling an item for pickup that doesn’t actually exist in the store.

3. In-store traffic patterns

- Customer and product flow — By aggregating and plotting RFID item movement throughout a store, retailers can begin to draw conclusions about how people and products navigate the physical confines of the space. Benefits could include: monetizing high-traffic endcaps, tracking in-store cart or product abandonment, removing physical pinch points, understanding how certain product categories or items correlate to different paths in the store at different times of day, days of the week, etc.

- Associate flow — Whether for training purposes or data collection, RFID system tags could be used to track employee movement throughout a store.

- Equipment flow — Whether it’s forklifts at a home improvement retailer or a restocking cart at a clothing store, valuable data can be gleaned from seeing how equipment flows through a store’s physical space.

4. Trial rooms

- Magic mirror — Imagine a fitting room that uses touch screen monitors in place of mirrors. By geo-locating specific RFID tags, this fitting room tracks the item that is being tried on, shows other available colors and what those might look like on you, shows available complementary clothes, and could provide relevant product information such as the fabric technology.

- Tracking pickup/try-on vs. purchased — As items are tried on and not purchased, that information can be tracked for either internal analysis or to remarket to the individual who didn’t purchase later.

5. Checkout process

- RFID system can speed up and potentially eliminate the traditional checkout process altogether. Items could pass on a conveyor through scanners that read on-the-fly rather than individual bar code scans. Items in a bag or cart could be tagged to a pre-loaded customer loyalty account to aid in creating a frictionless checkout experience where a customer simply walks through an RFID gate on their way out of the store.

6. Security improves with RFID in retail

- Theft — RFID movement tracking can be paired with sales data and video data to determine if items left the store in larger quantities than were purchased at that specific time. With this data aggregated, retailers can see systematically which exact items were stolen, which door they exited through, at what exact time, and have HD video of the specific perpetrator. This data can be actioned in real-time through alerts to associates, used for monitoring of general trends, or as evidence to work with authorities creating criminal cases.

7. RFID in Retail for Post-purchase enablement

- Another use case is linking product usage to marketing to create future sales. For instance, if a retailer’s app could track activities or read from other apps, it could enable unique capabilities. For one specific example, if running shoes were RFID enabled (the item itself, not the packaging), your phone or watch could recognize when you are wearing those shoes on a run. When the shoes approach expected end-of-life (based on miles run, user weight, user speeds) the retailer could trigger a coupon to replace that shoe with the newest iteration.

Conclusion: RFID system has a lot to offer retailers. They can identify every product in-store with a unique identifying number; they reduce the need for human resources and eradicate human error by automating processes; they enable simultaneous product scanning; offer real-time stock information; provide new ways of advertising; and increase security for staff, equipment, and stock.

ad

Comments are closed.